Animal Feed Machine

We can product all kinds of animal feed machines. Here are the details:

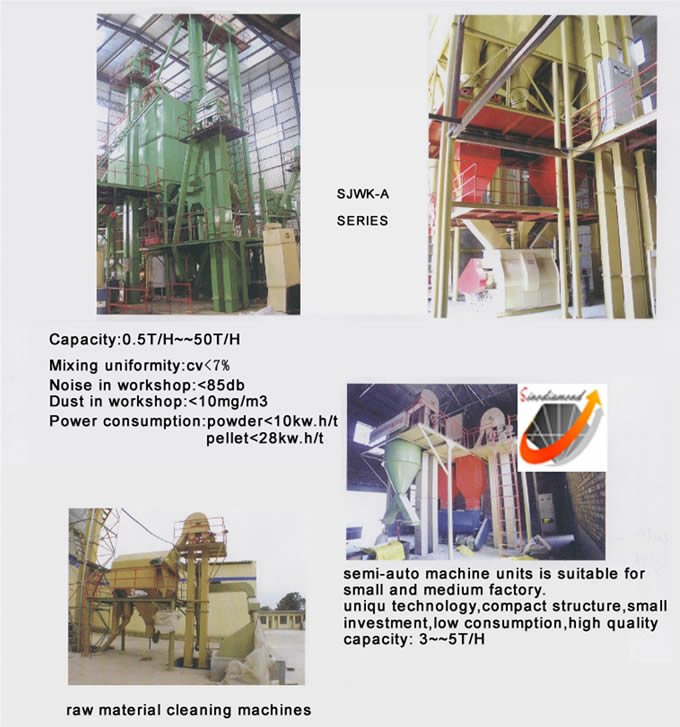

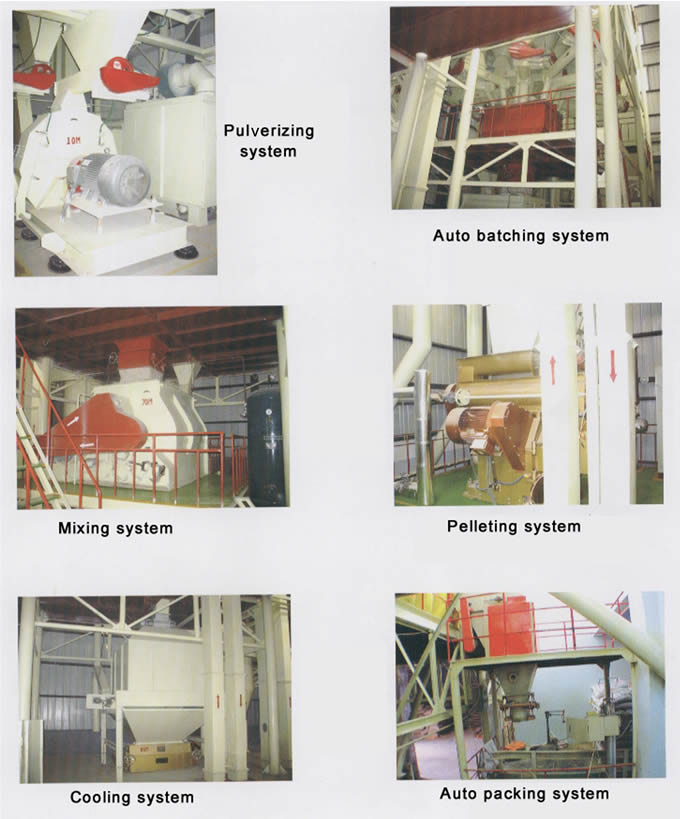

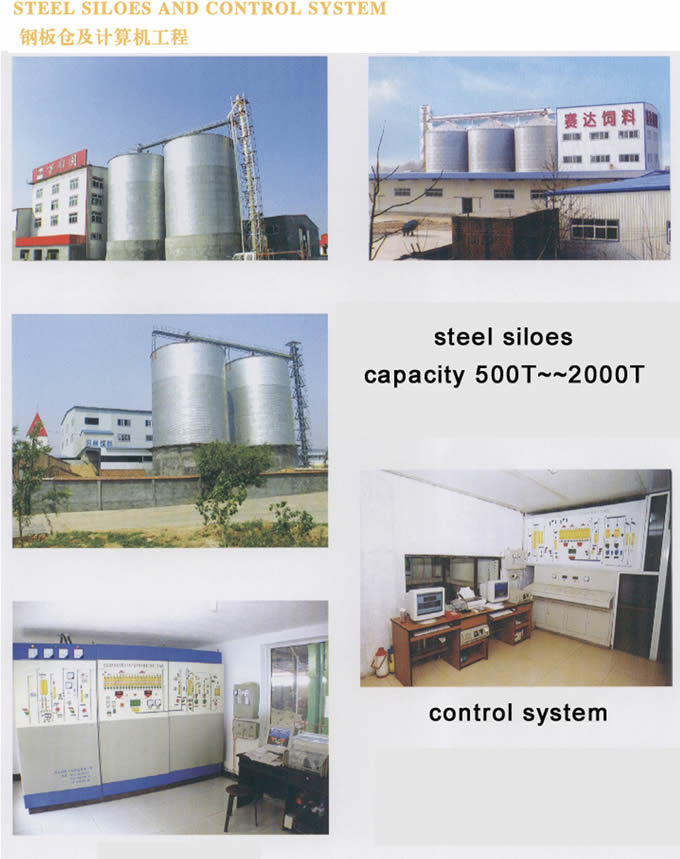

The line contains pre-mixing, magnetic concentration, crushing, dosing and mixing by persons or computer, pellet making, cooling system, screening, finished pellets packing and electric control cabinets simulation system.

Our feed machine have semi automatic and automatic kinds, the difference between them is the batching system. Semi automatic feed machine use manually to batch raw materials, automatic use computer to batch. Use different sizes of ring dies to produce different size pellet feed for different animals.

Powder feed section:

Use tear-circle hammer mill to crush the material into powder, double-shaft batch mixer to mix the feed materials, also can use additive mixer to add feed additive.

Pellet feed sections:

Use pellet mill to make pellet feed, just need to change different size of ring dies to change the diameter of feed. If for small chickens, can use crumbler to make.

Sort of feed: powder and pellet

Batching system: semi-automatic and full-automatic

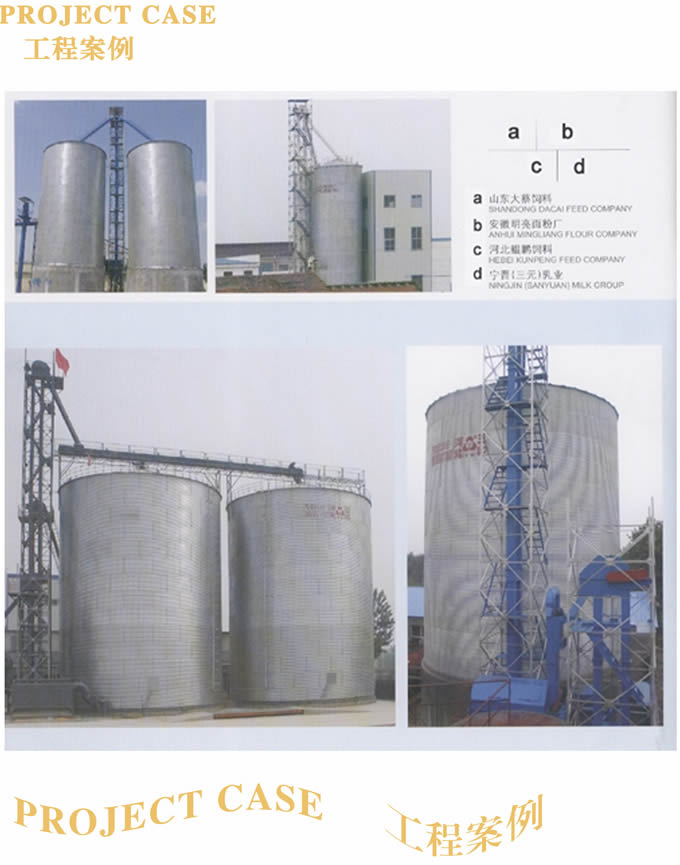

We can design complete machines according to your demands fully, and responsible for installation guide . Otherwise we can supply you one year wearing parts. If you are interested in our machines, please contact us without hesitating.

Welcome to visit our factory.

Specifications

In the conventional pelleting processes, meal conditioning with steam is a prerequisite for the compression of the meal or mash into pellets. Heat and water from the steam serve to activate binders in the meal particles (i.e. protein and carbohydrates), soften them and bring cohesive properties onto the surfaces of the particles. When the mash is compressed through a die, the particles are compacted and stuck together to form pellets. In the cold pelleting process of the present invention, liquid binders are used instead of steam. The binders have viscous and cohesive properties. When such a liquid binder is applied, free moisture penetrates solid particles in the mash while the viscous, cohesive substances in the binder agglomerate fine particles into larger particles and then remain on the surfaces of large solid particles, creating cohesive surfaces. When the moist, cohesive mash is compressed through a die, the particles are compacted and bound together to form durable pellets. Liquid binders used in the cold pelleting process can be any condensed liquid byproducts from the grain, food or feed processing industries. The liquid binders should have a solids content of 20-80% by weight, preferably 35-65%, and should have viscous and cohesive properties. Typical liquid binders include Brewex (a concentrated molasses-like by-product of the brewing industry), corn steep liquor, condensed porcine solubles, condensed distillery solubles, molasses, desugared molasses, sugar syrup, and condensed liquid whey.