Gabion Installation

- Gabions must be installed on a surface prepared to the levels and quality of the levels and quality of the enginner's specifications for the project.

- Rockfill for the gabions must be quarried rock of size and quality in accordance with the engineer's specifications for the project.

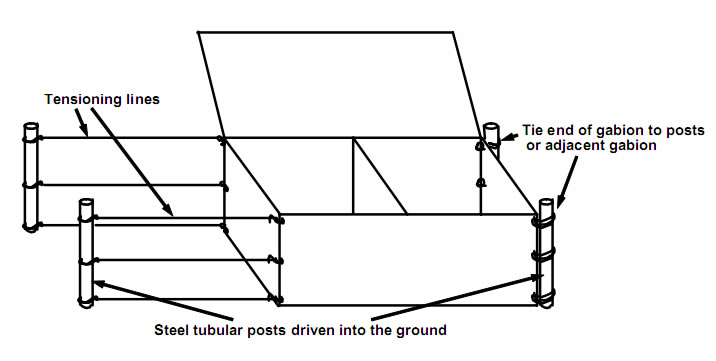

- Beforce filling, gabions should be placed on the prepared surface and tensioned to ensure that the shape is good and that exposed surface are smooth and taut. A suitable tensioning arrangement is shown in Figure 8.

Fingure 8: Tensioned gabion ready for filling.

Note: For speed of construction several gabions may be laced together end-to-end with fully laced joints as on their adjoining vertical edges and tensioned as a unit.

- Filling of gabions with rockfill may be by machine or hand tacking care to minimise voids. However , exposed face must be filled by hand using selected large pieces of rock with flat faces to give a fair face to the rockfill inside the expoaed geogrid face.

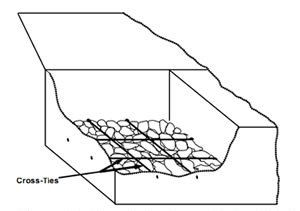

- If th gabion height (H) is more than 500mm then cross-ties of HDPE braid should be installed as shown in Figure 9 at vertical intervals of 250-400mm to improve stabilty and quality of finish.

Fingure 9: Cross-Ties in partially-filled gabion

- Slightly over-fill each gabion, using saller stones on the surface, to allow for settlement. Encourage settlement, for example by walking on the rockfill.

- Adjust finished surface of rockfill as needed.

- Equipment revetments

- Close down top of gabion and tightly lace, all edges and top-diaphragm joints.